Product Center – Winbosc DigiSpark

DigiSPark Digital Enhancement System

The equipment integrates digital hot stamping (convex hot), digital varnish, 3D crystal bright, partial glazing, braille, etc., personalized customized orders, variable data printing, special effects printing process. Cooperate with traditional printing, digital printing and other post-processes to realize the problem of digital printing post-processing

KEY TECHNICALS

Printing Method

UV Piezo-Electric, Drop on Demand inkjet Printing

Resolution:

360×360 dpi,Max 1440×360 dpi

Printing Speed:

6mpm – 30mpm (depending on printing thickness)

Supported Variable File Format:

PDF and varies barcodes format

Supported Image File Format:

PDF, PDF/VT, TIFF, BMP file formats

Substrate:

Offset, Digital Print, flexible material, thin film and other coated material

Image Size:

Max image width 288mm

Polymer:

LED UV Cure, deliciated transport varnish

Max Unwind Dia:

Max Roll Dia 700mm, core shaft @76mm

Max Rewind Dia:

Max Roll Dia 700mm, core shaft @76mm

Substrate Thickness:

30um-400um

Max Web Width:

330mm

Machine Dimension (LxHxW):

3,500 x 1,900 x 1,800mm

Production Environment:

Temperature: 15-30 degree celsius

Relative humidity: 40%-80% Non feezing

Power requirement

Voltage 3 x 380; +/-5%; 3 phase +G+N (Star connection)

Frequency:50、60Hz

Current : 25 Amperes

Capacity : Avg:13.5KVA @ Production

Max:30KVA

Cable Requirement: Min 50A

Frequency:50、60Hz

Current : 25 Amperes

Capacity : Avg:13.5KVA @ Production

Max:30KVA

Cable Requirement: Min 50A

Machine Weight:

approx 3000kg

PRINT TECHNIQUES

3D Shining

Spot varnish

Digital cold foil

EQUIPMENT ADVANTAGES

- All digital workflow

- Durability of embossing effect, will not deform

- Precise registration

- No need to plate make

- High added value

Technical Parameters

View the detailed product parameters PDF

Video Introductions

DigiSPark Digital Enhancement System Production Video

Paper Feed Part

Paper Feed Part

Full Color Digital Inkjet Unit

Flexo Unit

Cold Stamping and Film Covering Unit

Die Cutting Unit

Winding Unit

Paper Feed Part

01

The Ministry of feed

Adopt cantilever structure, easy operation and maintenance

Standard dust removal function, to solve the problem caused by dust

The corona device makes the material more adaptable

Unwinding diameter: 700mm, roll core 76mm

Paper Feed Part

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Full Color Digital Inkjet Unit

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Flexo Unit

Tab Content

Cold Stamping and Film Covering Unit

Tab Content

Die Cutting Unit

Tab Content

Winding Unit

Tab Content

Paper Feed Part

Full Color Digital Inkjet Unit

Flexo Unit

Cold Stamping and Film Covering Unit

Die Cutting Unit

Winding Unit

Paper Feed Part

01

The Ministry of feed

Adopt cantilever structure, easy operation and maintenance

Standard dust removal function, to solve the problem caused by dust

The corona device makes the material more adaptable

Unwinding diameter: 700mm, roll core 76mm

Full Color Digital Inkjet Unit

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Flexo Unit

Tab Content

Cold Stamping and Film Covering Unit

Tab Content

Die Cutting Unit

Tab Content

Winding Unit

Tab Content

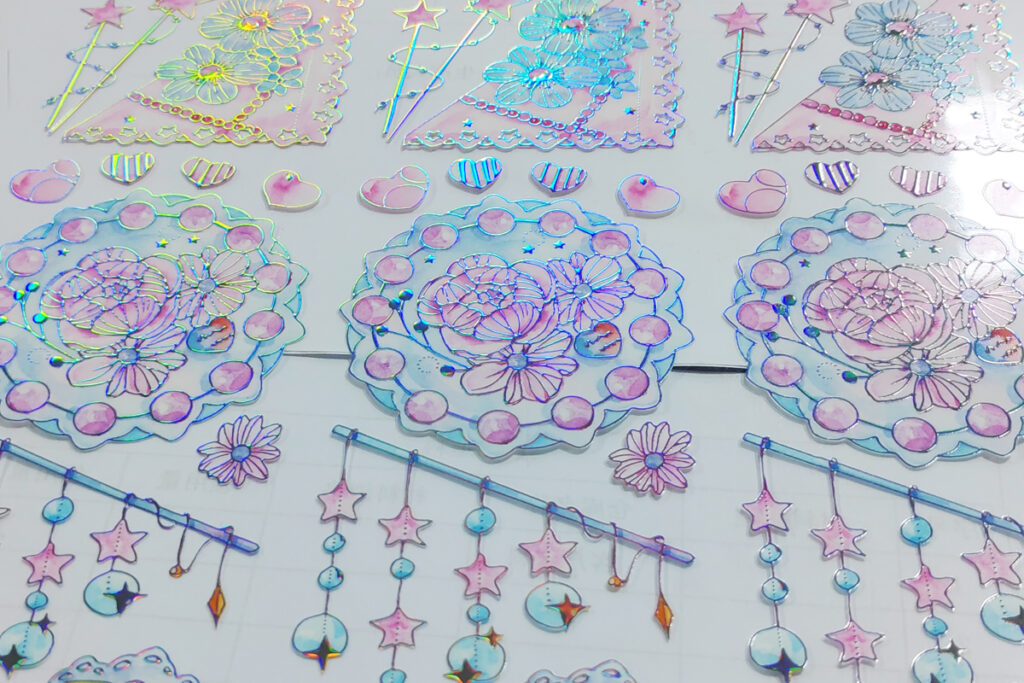

PRODUCT APPLICATION

Cosmetic products application

Wine products application

Food product application

Washi Tape